This article was taken from the July, 1969 Publication of "Archery" Magazine

Written by C.R. Learn

Bill Sweetland of Eugene, Ore. proves his ability to shoot and arrow as well as manufacture it. The buck is a blacktail he bagged in 1966 in Southern Oregon, it weighed in at 142 pounds. One arrow at 58 yards put him down.

Forgewood Arrows

By C.R. Learn

When Bill Sweetland goes hunting it may be different from other hunters' procedures. He may be in one of his favorite means of transportation, a canoe, and when he arrives in camp in the hinterlands of Oregon he sends a special delivery message home to let the family know he has arrived. This message system is even older than his canoe transport. Sweetland uses a homing pigeon to deliver his messages. This is one way an avid archer and manufacturer of a different and successful type of arrow material spends his spare time. Canoeing and the training of racing pigeons are two of the hobbies of Bill Sweetland, owner-operator of Forgewood Products in Eugene, Ore.

Sweetland has been in archery for many years and has an archer's knowledge combined with his forestry knowledge to give the hunting and target archer a product he can rely on and one which is constantly being upgraded. When Sweetland graduated from the University of California in forestry and wood technology he had been working on the idea of compressed cedar material for archery products. The idea continued to nag him as he worked for some time in his chosen field of forestry but it finally overcame his love of the formal type working day and he went into production with his Forgewood products and has been working with them ever since.

The idea of compressing Port Orford cedar to obtain a greater density and strength from an excellent arrow material and at the same time improve the qualities of cedar had been one of Sweetland's obsessions. He developed a process which gave him a better product in an already proven material. The exact process used for making Forgewoods is kept behind closed doors in Sweetland's plant, but he did explain the process in this manner.

The finest hand-split bolts of Port Orford cedar are obtained from the forests and hauled to the plant. These bolts measure 36inches long and every attempt is made to select those with the straightest grain structure. These bolts are stored in a warehouse to prevent end-checking, until they are required in the plant for basic working.

Terry Sweetland is shown operating air-operated saw carriage to cut cedar bolts. Saw making first cut on bolt in the first phase of Forgewood Arrows.

Until recently Forgewoods were available in two types, the "unfooted" and "footed" styles. Further research has brought the types of Forgewoods on the market to a constant called the Dura-Shaft. These are available in different grades but what Sweetland did is perfect an already good product and bring out an even better one. Since the Dura-shaft is the present product, this is the procedure for making it.

The bolts are cut at a varying thickness on a special saw carriage designed by Sweetland for this purpose. The saw cuts the bolts into wedges rather than flat boards. These wedges will be of constant thickness from one cut to the next by the control on the saw. When a board or wedge is cut on the saw the bolt is automatically turned so the grain will remain as straight as possible. If each board were cut with the thick end in the same direction it would eventually give a quartering grain structure and not what Sweetland wants in his product. The saw carriage reverses the bolt after each cut to obtain this straight grain characteristic.

When the wedges have been cut from the bolt, they are stacked in a production room and then placed into a hydraulic press where they are compressed with the proper time, temperature and pressure to obtain a flat compressed sheet the width of the cut board but now of even thickness but varying density. These compressed arrow boards are then placed back into a storage area to stabilize. If the boards were cut and doweled immediately they would possibly give varying shafts. The storing for a short time helps to bring the compressed wood back to a balance with the surrounding atmosphere. Using the specifications set by Sweetland for his Dura-Shafts and following the procedure used for wedge cutting, the board will have an increasing density from one end to the other. The smaller end of the arrow board will have less compression and therefore less density. The bigger end of the board will have the greatest compression and therefore the greater density.

When the arrow boards have been stored for the proper time they are next cut on machines to squares. These squares are then put into doweling machines and the almost finished shaft material comes out the other end. After the boards are stored and before being ripped into squares they are trimmed to 32 inches, which is the final overall length of the shafts. This is the last phase of the manufacture of Forgewoods but not the end of the product. As the shafts come from the doweling machine they are placed into a sander and sanded to an even, smooth finish.

After the final sanding they go to the inspection benches where they are not only checked by an electronic machine but by trained operators by eye. This gives many controls for maintaining the high quality of Forgewoods. The finished shaft after inspection and grading is then moved to an electronic spine tester where each shaft is spined and then sorted into the proper bin. To go one step farther they put all Forgewoods on a Shadow graph weighing machine to test the grain weight of each. When you receive an order of Forgewoods you can be assured each shaft has been through each of these steps and is matched very closely.

Forgewoods are made in five different diameters ranging from the light target style at 1/4 inch to the heaviest hitting weight size of 11/32 inch. To date Sweetland has never been stopped by an order according to spine requirements. They can give any spine in the 1/4 inch from the lowest up to 35 pounds. The other sizes (9/32 inch and 19/64 inch) are most popular, will graduate up to 11/32 inch which will give any spine from 75 pounds, the point where most Port Orford cedar shaft materials stop, up to no limit.

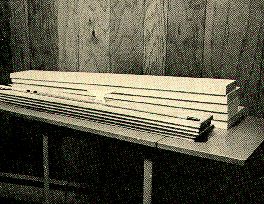

Left: Three phases of new Dura-Shaft. The planks are cut with a wedge shape. These blanks are then compressed to form the boards or blanks in front of the wedges and the final shaft, made into an arrow, rest on top.

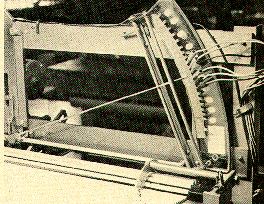

Right: After shafts are doweled and sanded, they are run through this automatic spine tester and sorted according to spine.

They have filled orders from the bins for a customer for shafts up to 140 pounds spine. These are in regular length hunting shafts. They maintain a supply of heavy spined shafts and this gives the big bow puller a quality shaft material at a spine he will know is true. Conversely the smaller diameter and spine control makes an excellent hunting shaft for the light bow hunter who hunts with the 40 or 50 pound bow. The smaller diameter gives better flight and a faster arrow, the weight gives good penetration for the shaft size. This gives the man and wife hunting team the extreme range of fine hunting shaft material from the smaller diameter shafts usually required by women hunters to the bigger and stronger shafts for the men. You name your requirements and Forgewood has the arrow for it.

The basic theory behind the Forgewood Dura-Shaft has been derived by Sweetland over the years and isn't just a quick idea. He made two styles of shafts for many years, the unfooted and the footed styles in his different grades. He now has incorporated the better qualities of both designs to obtain the Dura-Shaft. To give the Dura-Shaft a fast description it might be called a tapered shaft construction with parallel sides. The front section of an arrow does little bending around the bow and therefore can be stiffer or denser than the back section. Sweetland varies the compression of the Dura-Shaft in his wedge cutting and equal compression and the finished shaft has densities of varying hardness in compression to a standard type cedar shaft material.

If you compared the hardness of a Dura-Shaft tot that of a regular Port Orford cedar shaft it would be like this: The nock end would have the lower density. This is because the back of the shaft where the nock goes moves around the bow as it is shot and needs some flexibility and also requires less density as it receives little or no shock in comparison the the point. The hardness at the nock end is 1.5 times harder than regular cedar shaft material. The center of the shaft is harder than the nock end to give it better spine and to slow down the oscillation of the arrow as it bends around the bow and vibrates down the range. The density of the center section is 1.9 times harder. This makes the shaft stiffer and also allows Sweetland to make the Forgewoods of more slender diameters than natural cedar. The tip of the shaft receives the most impact, the most punishment and therefore has the greatest density in the Dura-Shaft. This density is 2.3 times the standard cedar material and gives the Dura-Shaft the qualities of a footed shaft without the extremes the older footed shafts had. The end product will perform similar to a tapered shaft which is made by some serious archers but has parallel sides, as any standard shaft material. The end result is a shaft material which can handle any bow weight from either extreme, when doweled to various diameters.

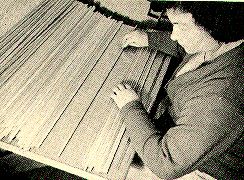

Shirley Wilnot makes a visual check on shafts as a

further inspection in the Forgewood plant.

Forgewoods are not only found in the hunting and target field but can be found in some unusual places. For many years the flight records have been set with Forgewood shaft materials. These little flight arrows will average a length of 18 to 19 inches and are barreled and much work and skill goes into making them. One flight archer mentioned if he sold his flight arrow he would have to get at least $10.00 each for the time and work involved in making them. They chose and used Forgewood for these exacting arrows. One other place you will find Forgewood products is in the crossbow field. Sweetland makes and sells crossbow bolts of great variety, using different sections of his shaft material, and he can just about meet any crossbow bolt requirement.

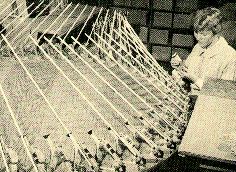

Left: Susan Satziol uses a Shadowgraph to weigh match shafts which have been spined. This gives the shafts a spine and weight conformity as they are mailed to dealers and archers.

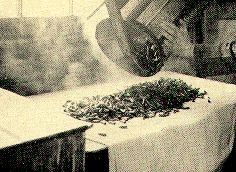

Right: Sweetlands Match-All points are poured from the container.

To complete his archery products Sweetland is continually working on new ideas. Not too long ago he came out with Fur Fletch, a rabbit fur dyed different brilliant colors and backed with an adhesive which can give the indoor archer and instant arrow material. This Fur Fletch works fine indoors and prevents breaking and damaging fletchings. It has enough stability to hold the shaft from target bows in good flight and is great for the shorter ranges and other rough treatment. To replace, all you have to do is pull off the adhesive material, clean the shaft and replace with another strip of Fur Fletch. Bow hunters, as well as target archers, are using this increasingly as a tracer behind regular feathers, by winding a single wrap of the fur strip just forward of the nock. The visibility of this after the arrow strikes is amazing.

Perhaps another product many archers feel is of greater use is the Match-All points made by Sweetland. These are field points, blunts and target points turned from steel which fits flush and even on the shaft. This gives a cleaner arrow for bale shooting since they pull out very smoothly with no hang-up as some field points will have. These points are made on automatic screw machines at the plant and they make them to fit all their arrow products. You can get field points form 1/4 inch to 11/32 inch and sizes in between, and the same in target points and blunts. All are made with taper hole fitting to the shaft and this makes them interchangeable with broadheads for hunting and stump shooting. Some target points are also made with parallel holes.

Left: The arrow making section where the finished Forgewoods are crested. Here they are being fletched.

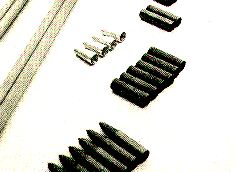

Right: A cross section of other Sweetland products includes the Match-All field point in the foreground, taper-hole blunts and in front, Sweetland's patented Headshrinker.

When Sweetland made his smaller diameter shaft materials he had an unexpected problem. How could an archer take his 5/16 or smaller size shafts and mount an 11/32 broadhead of his choice to the shaft and not have a sloppy fit? With a little work and a good knowledge of archery Sweetland devised and patented his Head-shrinker. This is an aluminum adapter which will allow any size broadhead or field point to be mounted on a smaller shaft. For example, if the little woman wants to go hunting with you and you decide to get her a set of Dura-Shafts in the 9/32 inch diameter to match her bow and draw length, you might have problems finding any 9/32 inch broadheads. If your favorite head is only made in 11/32 inch, for example, you will have a sloppy fit on that arrow.

The Head-shrinker solves this. You apply a little epoxy cement or Ferr-L-Tite and tap the Head-shrinker firmly into the broadhead, then cement the whole unit to the shaft where it fits the smaller diameter nicely. This give the shaft a solid fit to the Head-shrinker, the broadhead has a solid base and it all flies beautifully.

Sweetland continues to work and test his products and through these tests he comes out with new products such as his Head-shrinker and his new Dura-Shaft. He has a good product and has many hunters who prefer his shaft materials, including Ben Pearson who has used Forgewoods for hunting for years. You might keep your eye on the Northwest, you never know what will happen next.

Sweetland Archery Products Add in "Archery" Magazine July, 1969

|

E-Mail to: arrowsak@alaska.net Back to AFA Home Page